Paula Rodrigues – INESCTEC

- Project name:

Developing Low and Zero Carbon Solutions using NetMIX technologies

- Project description:

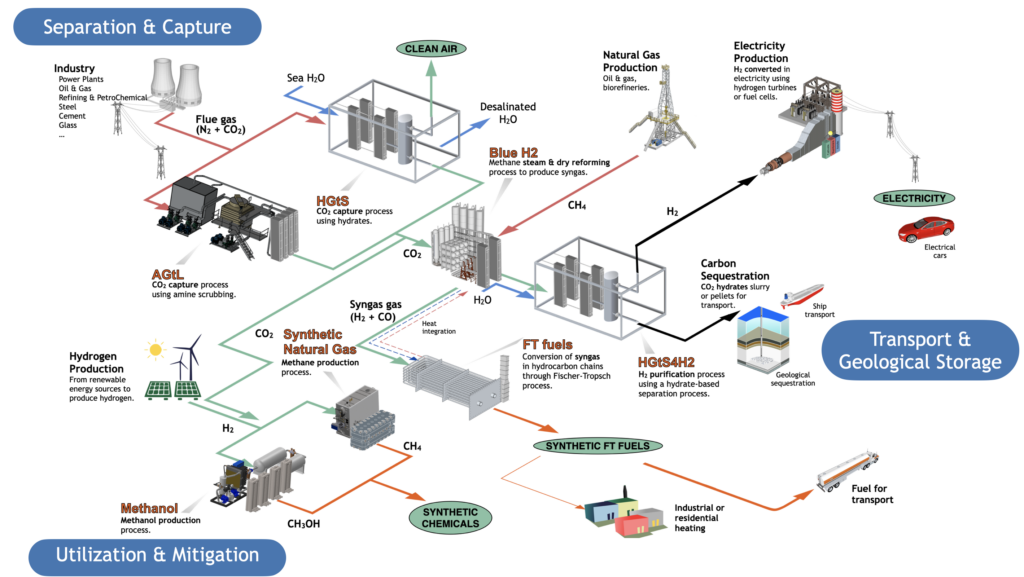

The CoLAB Net4CO2 is focused on the development of different solutions for low and zero-carbon energy systems, helping different industries to reach carbon neutrality by 2050 and meet the targets defined in the Paris agreement. Three main strategic vectors are being explored: CO2 separation and capture, CO2 utilization and mitigation and CO2 Transport and Geological Storage. Within each vector, different technological options are been explored, as represented in Figure 1.

MACC facilities have been used to run 2D and 3D Computational Fluid Dynamics (CFD) in Ansys Fluent for fundamental understanding and design optimization of devices used for 3 main applications:

- carbon dioxide capture via hydrate formation;

- carbon dioxide utilization via synthetic fuel (methanol, Fischer-Tropsch liquid hydrocarbons and methane) production;

- hydrogen combustion.

These devices are based on the NetMIX technology, developed at the University of Porto, in 2004, which consist of a network of mixing chambers interconnected by transport channels where the fluids flow in a self-sustained oscillatory motion, with an outstanding heat and mass transfer performance. These features are essential for an efficient removal of the heat of reaction, critical to maintain hydrates stability or avoid the occurrence of hot/cold spots in a synthetic fuel reactor or combustor, as well as for an effective contact between different phases and species. In addition to that, inside the chamber the fluid flows with a wall-sweeping pattern, which has the potential to reduce several catalyst deactivation mechanics, a common limitation in the development of catalysts for carbon dioxide utilization.

However, this flow character together with the presence of multiple phases, and the occurrence of reactions, some of them with very fast kinetics, require a very strong computational power, to be simulated in a reasonable amount of time. The use of MACC facilities is a valuable accelerator for this development. It is estimated that in some cases, the simulation wall clock time can be reduced from months to days.

The video below presents the results obtained for a multiphase CFD simulation (right), which is accurately representing the experimental observation (left). These simulations required about 5.33 CPU/h. Until September 2021, 87% of 1.024 M CPU have been used by Net4CO2.