Topics: Polymer Processing, Computational Rheology, Industrial Process Simulation

In our daily life polymeric based soft materials play an indispensable role, being present in a wide variety of products such as clothes, toothbrushes, car components, plastic hangers, toys, paint, etc. Due to their complex structure, their behavior induces complex, sometimes counter intuitive, phenomena, which are difficult to predict. The design of systems involving those complex behavior materials is usually a challenging task, that can clearly benefit from the support of numerical modeling codes, an area usually denominated by computational rheology.

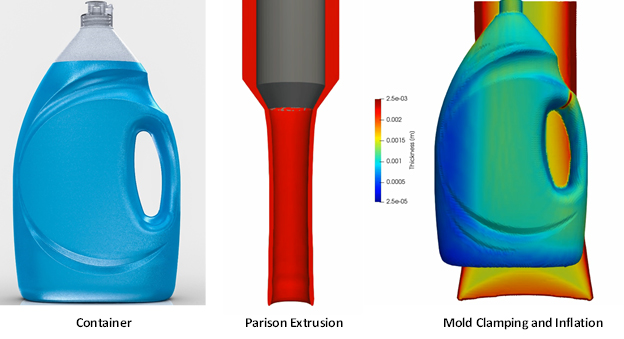

The extrusion blow molding (EBM) process is one of the most employed to manufacture hollow containers. Along the process the melted material is shaped and, after cooling, solidifies to retain its shape. The EBM process presents several degrees of freedom that are usually set by the designer following experimental trial-and-error procedures, which are very resource demanding. Knowing that the time-to-market is increasingly important, any approaches that help minimizing the time spent on the process setup bring clear advantages.

The University of Minho and Logoplaste Innovation Lab have been working together, for more than two years, on the development of numerical codes able to simulate all stages of the extrusion blow molding process. The initial versions of the codes comprise simplified models, but allowed promising results for simple geometries. Having in mind the advantages of those approaches, the team has been working on improved versions of the codes, which consider increased accuracy constitutive models for polymeric materials. This comprises a more demanding simulation framework, since it requires the track of supplementary coupled variables. These additional requirements increase the calculation time significantly and makes it impossible to obtain results in a timeframe compatible with the industrial needs, using regular desktop computers. These difficulties are even more serious when calculation loops are required to look for the optimum solutions.

This project aims at porting the simulation tool under development to HPC systems, assessing and optimizing its performance, and coupling it with optimization tools. The work also comprises experimental assessment with industrial case studies, which should allow quantifying the benefits of the envisaged approaches.